By Chinthaka Perera,

Deputy General Manager of Manufacturing Operations, BSC Eng, MBA.

Supplier Integration is a key component in an organization’s operation strategy which ultimately leads to a competitive advantage. In this instance, ERP systems come in handy as they allow organizations to run their business processes in a smooth fashion including the supply chain. Implementation of an ERP solution allows a company to integrate suppliers into the system. As of today, XYZ Company hasn’t used the SAP-ERP to full extent the supply chain area and they need to capitalize more on the supplier integration part of the ERP system. Therefore, the main objective of this study is to understand how the ERP system used in XYZ Company influences SupplierIntegration. The scope was limited to local manufacturing plants and their key local suppliers.

This research study had carried out based identified four hypotheses which consist of four variables, Information Integration, Collaborative Planning, Coordinated Workflow, and Flexibility of ERP system. Data collection was done based on a questionnaire and on the findings, it was identified that three hypotheses have a positive relationship while one hypothesis has no relationship. Recommendations and future research opportunities were also discussed below.

Keywords:

Supplier Integration, ERP Systems, Information Integration, Collaborative Planning, Coordinated Workflow, Flexibility of ERP System

Background of the study

The Apparel Industry has grown in a rapid pace in the recent past as customers are intensely following fashion trends all around the world. Apparel Manufacturing dominance has been shifting towards developing and fast-developing countries in Asia and South American continents from the last few years of the 20th century. Apparel manufacturers were shifting their manufacturing bases to Asian and South American countries due to cheap labour, low production cost (low material cost), and willingness in people to work due to their unbearable unemployment circumstances.

Sri Lanka entered the apparel industry in the 1960s producing and mainly catering to local demands. Then the industry was expanded for export-oriented production in the 1970s. After the liberalization of the economy in 1977, Sri Lanka was able to attract foreign garment export giants and reallocate their well-established apparel and textile business in the country, both in urban and rural areas mainly due to labour costs. During the 1980s, apparel exports grew rapidly due to incentives granted by the Board of Investment of Sri Lanka (BOI). In 1992, BOI launched a special program offering attractive incentive packages to all apparel manufacturers to promote the industry in rural areas of Sri Lanka. Consequently, in 2014 the industry grew to 36% of all exports of the country. As of 2015, over USD 5 billion exports were generated and nearly 300,000 Sri Lankans were occupied as direct employees. (Anon., 2006)

Objectives of the research

The main objective of this research is to analyze the ERP system connectivity influence on supplier integration in XYZ Company to improve the efficiency of supply chain management systems.

The following sub-objectives are formulated in line with the research problem.

- To explore and determine the level of supplier integration in XYZ Company

- To evaluate the impact of the current ERP solution on supplier Integration and identify the elements that will further enhance the supplier performance in achieving on-time material delivery flow.

- To identify best practices on supplier integration systems and give recommendations for improvement in supplier integration through ERP systems.

Significance of the Study

Although supplier integration is not a new concept in the modern business environment, different factors will affect the effectiveness of supplier integration in different business scenarios. And also, it varies from region to region. After a deep analysis of the literature, it was understood that there was very little research work existing around Supplier Integration in related to Sri Lanka Apparel Industry. So this study will be beneficial not only to XYZ Intimates but also to all apparel manufacturing companies in the country.

This study will also give an opportunity to identify the areas that XYZ Company to give further attention to supplier Integration on their Lean journey. The ultimate objective of XYZ Company is to manufacture the best quality apparel products at the lowest cost with a shorter lead-time and to become the most competitive vendor for their world-famous customers like Victoria’s Secret, Nike, etc. So, it is very important to optimize the supplier integration process and achieve the Just-In-Time material flow which will directly reduce the product cost and lead time. Therefore, this study will be beneficial to the XYZ Company as well as their customers.

Research findings will be a good insight for XYZ Company to strengthen their supplier relationship by sharing the possible improvements. Thus, this study will create a win-win situation for both XYZ Company and its suppliers.

a. Limitations of the study

A few limitations are identified when carrying out this research and those limitations are listed below.

- This study is extremely targeted at local supplier integration as factors affected by foreign suppliers will be different.

- Thus, the focus is given only to XYZ Company, and this study does not cover the whole apparel manufacturing industry.

- Out of the identified factors that are related to supplier integration, only four factors are considered for this study. Those 4 factors will be articulated to build the hypothesis and questionnaire to gather sample data for analysis.

- Any technical requirements/ characteristics for supplier integration are not considered in this study.

- XYZ Company has more than 30 local suppliers. But for this study, only main local suppliers are considered based on volume and value.

Conceptual Framework of the Research

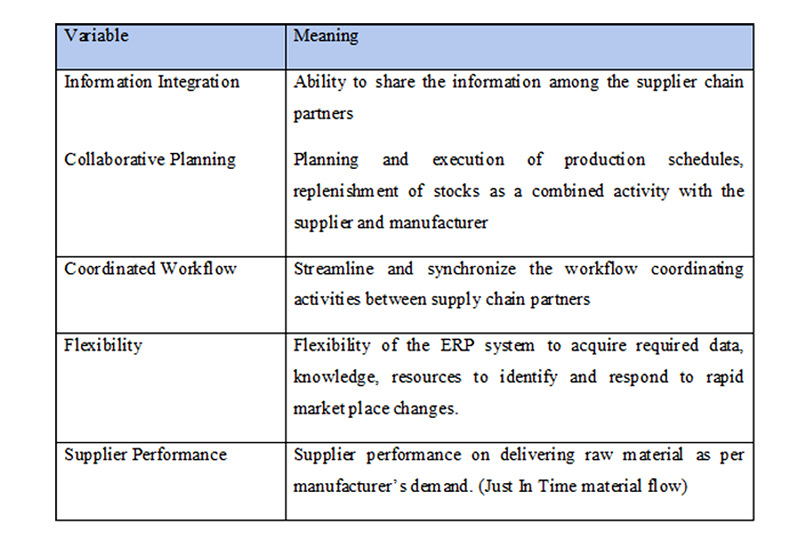

The purpose of this study is to identify and understand the influence of the ERP system connectivity on supplier integration in XYZ Intimates to improve the efficiency of supply chain management systems. Based on the literature reviewed, the identified variables can be described as follows.

Table 4: Discerption of variables

Source: Developed by the researcher

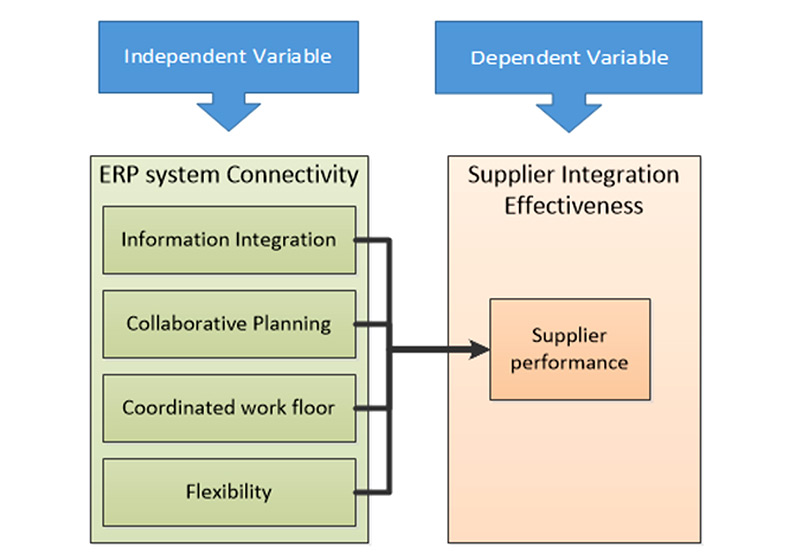

Considering the above variables, the conceptual framework graphically can be illustrated below

Figure 7: Conceptual Framework

Source: Developed by the Researcher

Development of Hypotheses

Developing relevant hypothesis are very important as it will help to create the logic and relationship between identified variables for the study. It also will help the researcher to focus and do the analysis and arrive at conclusions as per the research objectives. Hypotheses are tentative statements that predict what you finally expect to find in your research. (Uma Sekaran & Roger Bougie, 2010).

Based on the conceptual model illustrated in Figure 7, the following hypotheses are developed. These hypotheses are validated using advanced statistical techniques in this research.

Information Integration

H1a – There is no relationship between Information Integration through ERP system and supplier performance.

H1b – There is a relationship between Information Integration through the ERP system and supplier performance.

Collaborative Planning

H2a- There is no relationship between collaborative planning and supplier performance.

H2b- There is a relationship between collaborative planning and supplier performance.

Coordinated Workflow

H3a- There is no relationship between the Coordinated workflow of supplier & manufacturer and supplier performance.

H3b- There is a relationship between the Coordinated workflow of supplier & manufacturer and supplier performance.

Flexibility

H4a- There is no relationship between the flexibility of the ERP system and supplier performance.

H4b- There is a relationship between the flexibility of the ERP system and supplier performance.

Hypothesis – Information Integration

Since the Pearson correlation is 0.377, it denotes that there is a positive weak relationship between information integration and supplier performance. According to the statistical model, the P value ( 2-tailed) is 0.000. Therefore at 95% confidence level the alternative hypothesis, H1b can be confirmed.

Also, it is emphasized that the relationship between information integration and supplier performance is significant by having a 0.000 Sig value.

As per the R-square value, the overall contribution of information integration to supplier performance is 14%. In addition to that, the regression analysis reveals that a unit increase in information integration will lead to a supplier performance increase of 0.344 units. The above findings show that information integration has a considerable impact on supplier performance. Also, it is indicated that the ERP system connectivity of information integration of XYZ Company and suppliers is not at a satisfactory level as the mean value is 2.98.

The above findings were emphasized by the several scholars in their articles as mentioned in the literature review. David Hwang and Hokey Min ( 2015), Hau Lee and Seungjin Whang ( 2001), and Kolberg and Dreyer (2006) pointed out that information integration has a positive relationship with supplier performance.

5.2.2 Hypothesis – Collaborative Planning

As per the analysis in Chapter 4, there is a very weak positive relationship between collaborative planning and supplier performance. According to the statistical model, the P value (2-tailed) is 0.123. Therefore at 95% confidence level, the alternative hypothesis is rejected and the null hypothesis is accepted (H2a). On the other hand, having a sig value more than 0.05, it is confirmed that the relationship between collaborative planning and supplier performance is not significant. Further, as per the R-square value, the contribution of collaborative planning to supplier performance is only 2.7%. In addition to that, the regression analysis reveals that one unit increase of collaborative planning will have only 0.132 times impact on supplier performance. Therefore, it is denoted that collaborative planning has a minimum impact on supplier performance. However, Dudek ( 2009), Kilger and Reuter (2008), and Hau Lee and Seungjin Whang (2001) have emphasized that collaborative planning will affect the supplier performance.

5.2.3 Hypothesis – Coordinated Workflow

Since the Pearson Correlation is 0.263, it denotes that there is a positive weak relationship between coordinated workflow and supplier performance. According to the statistical model, the P value (2-tailed) is 0.013. Therefore at 95% confidence level the alternative hypothesis, H3b can be confirmed. The above result can be verified again by having respondent’s feedback of 51% as “Agree” on the questions on coordinated workflow. Further, since the Sig value is 0.013, it is confirmed that the relationship between coordinated workflow and supplier performance is significant.

As per the R-square value, the overall contribution of coordinated workflow to supplier performance is 6.9%. In addition to that, the regression analysis reveals that a unit increase in coordinated workflow will lead to a supplier performance increase of 0.221 units. The above findings show that coordinated workflow has a considerable impact on supplier performance. These findings are supported by scholars such as David Hwang and Hokey Min (2015), Max (2014), and Orion (2016) in their research articles which are mentioned in the literature review.

5.2.4 Hypothesis – Flexibility of ERP System

Pearson Correlation of hypothesis, the flexibility of ERP system is 0.271. It indicates there is a positive weak relationship with supplier performance. According to the statistical model, the P value ( 2-tailed) is 0.011. Therefore at 95% confidence level the alternative hypothesis, H4b can be confirmed. Further considering the Sig value which is less than 0.05, we can confirm that the relationship between the flexibility of ERP system and supplier performance is significant. On the other hand, as per the R-square value, the contribution of the Flexibility of ERP System to supplier performance is 7.3%. In addition to that, the regression analysis reveals that one unit increase in the Flexibility of ERP System will have a 0.174 times impact on supplier performance.

5.3 Recommendations

Supplier integration is an essential component in supply chain management and successful supplier integration can lead to sustainable competitive advantage. An ERP system will be a key consideration in supplier integration. XYZ company has been working with supplier collaboration and integration for more than two decades. Similarly, one of the best ERP systems in the world, SAP has been used in XYZ since 1998. Still, there is an opportunity to improve supplier integration while progressing the lean journey to achieve the “Just In Time” material flow. Based on the study findings.

- It is recommended to re-visit the Information Integration mechanism with suppliers because the respondent’s feedback is not at a satisfactory level at the present situation as the mean of the questioner is below 3.

- As per the analysis, there is a positive weak relationship between collaborative planning with supplier integration. Anyway, regression analysis reveals that the relationship between collaborative planning and supplier performance is not significant. However, looking into the mean value of the questions, still there are opportunities to improve the planning process with suppliers. These will be elaborated on later in this chapter.

- Coordinated workflow is also a necessity in supplier integration. XYZ Company has opportunities to improve the coordinated workflow between suppliers to eliminate the duplication of work.

- ERP system flexibility is another key consideration in supplier integration. XYZ Company has to pay more attention to the flexibility of the current ERP system as the mean of the questionnaire is below 3.

Based on the questionnaire feedback and data analysis, the below recommendations are made to improve supplier integration in XYZ Company.

- Establishment of real-time data access between supplier and manufacturer.

- Establishment of a process to access all required information for the decision-making

- Accuracy of the information available.

- Mitigating the risk of information sharing

- Establishment of long-term partnerships with suppliers

- Enhancing standardized and synchronized processes with suppliers.

- Coordinated R&D to improve supply chain efficiency.

It is recommended to further improve joint R & D to improve supply chain efficiency.

- Improving the flexibility and compatibility of ERP systems.

a. Suggestions for Future Researchers

This research mainly focused on local suppliers, and factors and findings may be different for overseas suppliers. It is recommended to continue the same study for the overseas suppliers as well. Further, this study is mainly done with apparel manufacturers and suppliers. The same research can be carried out for other industries.

REFERENCES

Akkermans, H. A., Bogerd, P. &Yucesan, E., 2003. The impact of ERP on supply chain management. European Journal of Operational Research, pp. 284 – 301.

Al-Mashari, M. & Abdullah, A.M., 2003. Enterprise resource planning: A taxonomy of critical factors. European Journal of Operational Research, 146(2), pp. 352- 364.

Beal, V., 2012. IT Business Edge, Webopedia. [Online] Available at: https://www.webopedia.com/TERM/E/ERP.html. [Accessed Feb 2018].

Bohnenkam, T., 2013. The effect of the resource-based view on decisions in supply management. 1st IBA Bachelor Thesis Conference, University of Twente, Faculty of Management and Governance.

BOI- Board Of Investments. [Online] Available at: http://www.investsrilanka.com/key_sector/apparel/apparel_overview

Cagliano, R., Caniato , F. & Spina, G., 2012. The linkage between supply chain integration and manufacturing improvement programmes. International Journal of Operations & Production Management, 26(3), pp. 282 – 289.

Chang, I.-C., Hwang, H.-G., Liaw, H.-C. & Chen, S.-L., 2008. A neural network evaluation model for ERP performance from SCM perspective to enhance enterprise competitive advantage. Expert Systems with Applications, 34(4), pp. 1809- 1816.

Chen, I. J. &Paulraj, A., 2004. Towards a theory of supply chain management: the constructs and measurements. Journal of Operations Management, 22(2), pp. 119- 150.

Chen, I. J. &Paulraj, A., 2014. Towards a theory of supply chain management:. Journal of Operations Management, pp. 119 – 150.

David Hwang & Hokey Min, 2015. Identifying the drivers of enterprise resource planning and assessing its impacts. Industrial Management & Data Systems, 115(3), pp. 541- 569.

5 comments

Being in the manufacturing industry for 20 years , I felt this study is done based on a valid point and I recommend every one to have an idea on this and it is worth having this article

ERP systems act as a vital tool for aggregating and providing a worldwide perspective on supply chain data, furnishing businesses with a comprehensive, real-time overview of their performance. This empowers them to promptly make informed decisions for enhancing operational efficiency and effectively addressing any challenges that arise. In addition, ERP systems automate crucial supply chain functions, leading to an acceleration in responsiveness, a reduction in administrative burdens, and a mitigation of the risks associated with human errors. The researcher’s meticulous selection of variables for managing this research analysis is highly commendable and underscores their keen attention to detail.

The integration of ERP systems within the context of supplier integration is an intriguing and relevant area of study. As businesses continue to evolve in an increasingly globalized and interconnected world, the effective management of supplier relationships has become a critical factor for success. ERP systems play a pivotal role in streamlining and enhancing these relationships, providing a centralized platform for managing data, communication, and transactions with suppliers.

This research is significant as it can shed light on how ERP systems impact supplier integration in various industries and organizational settings. It can investigate the benefits and challenges associated with ERP implementation, the impact on supply chain visibility, cost reduction, and process efficiency. Furthermore, this research could explore the role of ERP systems in promoting sustainability and ethical sourcing practices, a growing concern in today’s business landscape.

The potential for enhancing supplier integration through ERP systems also extends to risk management, as these systems can help businesses proactively identify and mitigate supply chain disruptions. Therefore, the research can explore how ERP systems contribute to resilience in supply chains.

In addition, the study should delve into the technological advancements and emerging trends in ERP systems that may further shape supplier integration practices. Moreover, it can consider the human factors and change management aspects associated with ERP adoption, as successful integration often relies on how well employees and partners adapt to new systems.

In conclusion, research on ERP systems in supplier integration is not only timely but also holds great promise for uncovering valuable insights that can benefit businesses across various industries. It has the potential to inform strategic decision-making and contribute to the evolving landscape of supply chain management.

[…] post ERP SYSTEM FOR SUPPLIER INTERGATION appeared first on […]

Put this for this article

ERP can significantly improve supply chain processes by making them more scalable, efficient and easy to manage. These systems help businesses integrate data from across the supply chain, streamline and automate key processes and gain better supply chain visibility to help improve efficiency and respond to problems.

Writer had made tremendous effort in data analysis & for comparison of data before & after.

Appreciate the effort & the attension to detail provided in analyze